How to Bend Guitar Sides with a Silicone Heater?

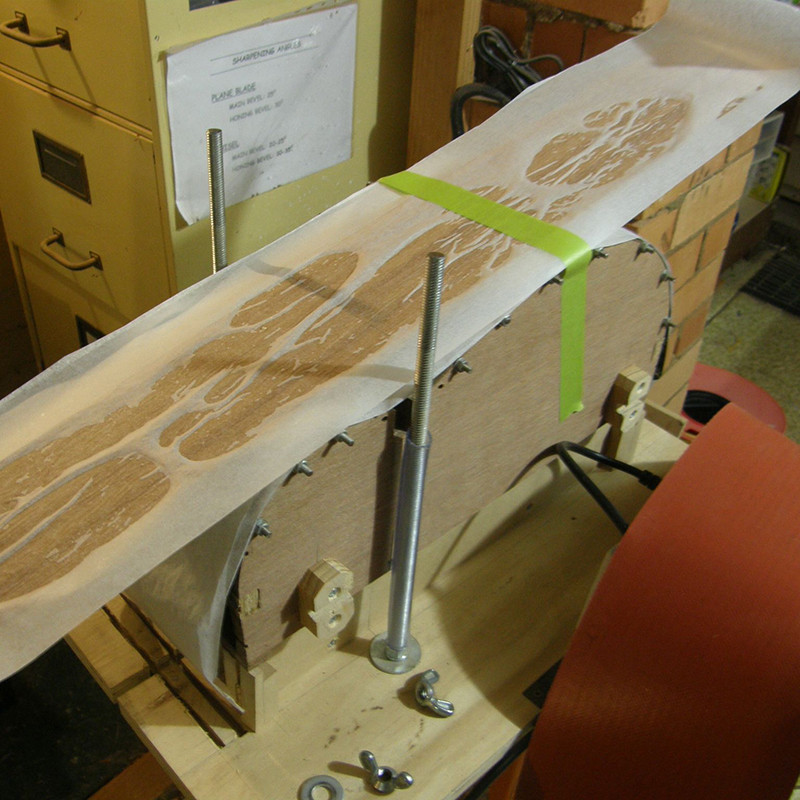

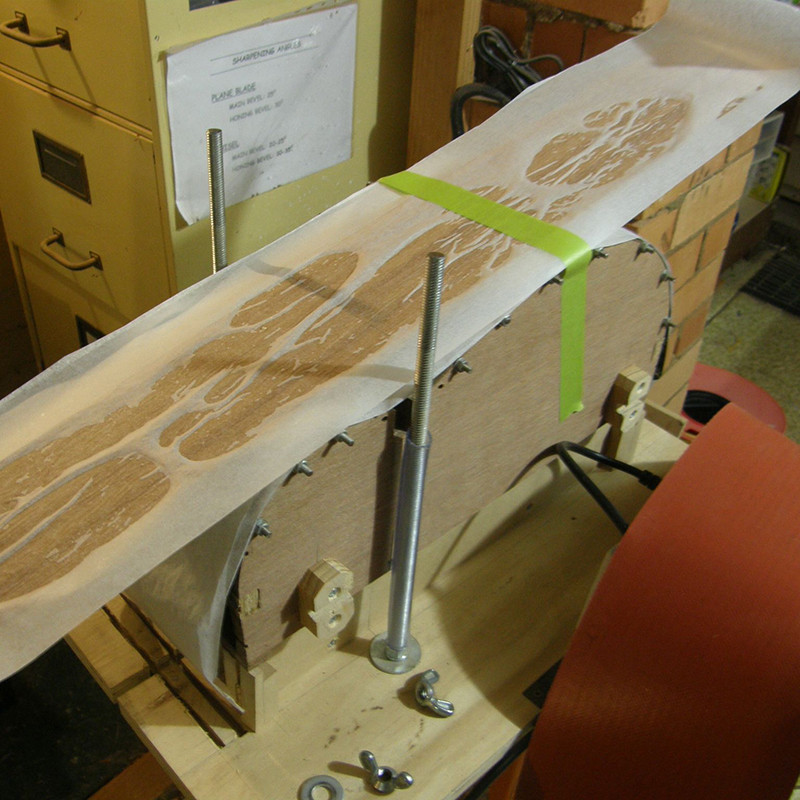

The side bender is a hollow mould on a base, with a waist clamp to draw the wood down into the concave bend and two clamps each at

the head and tail to draw the side around the convex curves:

The sides of the mould define the shape, and it’s useful to slightly exaggerate the curves because the bent wood always

springs back a bit when it’s removed. Around the edge of the mould you can see the ends of the rods that go from one

side to the other to form the actual bending surface.

The clamps are made from threaded rod and wingnuts from the hardware shop. You can’t see the end clamps that pull

the front and back downwards to put the whole piece under tension, but they’re just eyebolts with a wingnut on each

that act on the undersurface of the mould base.

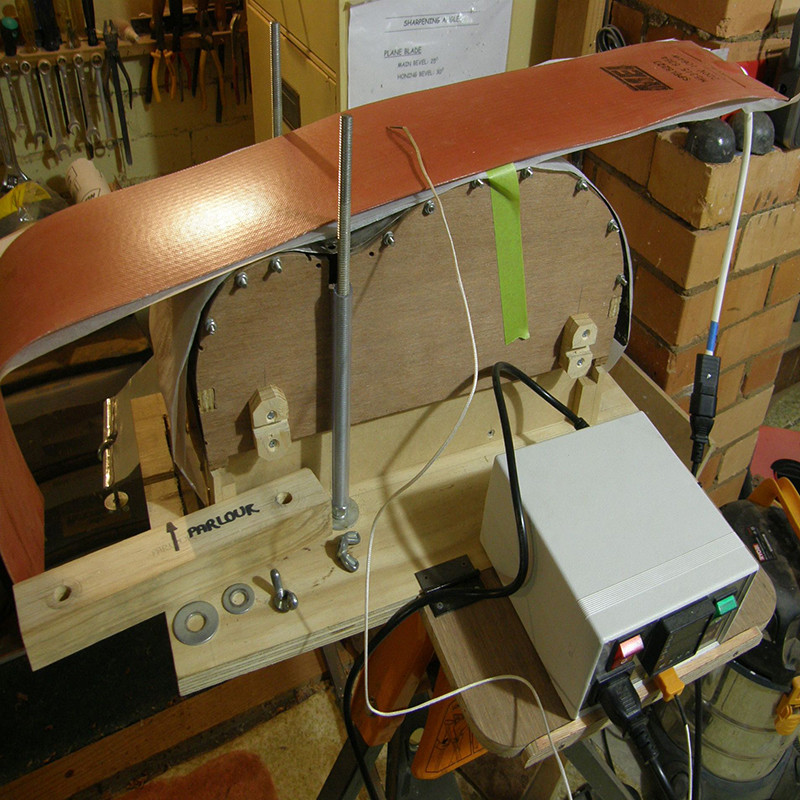

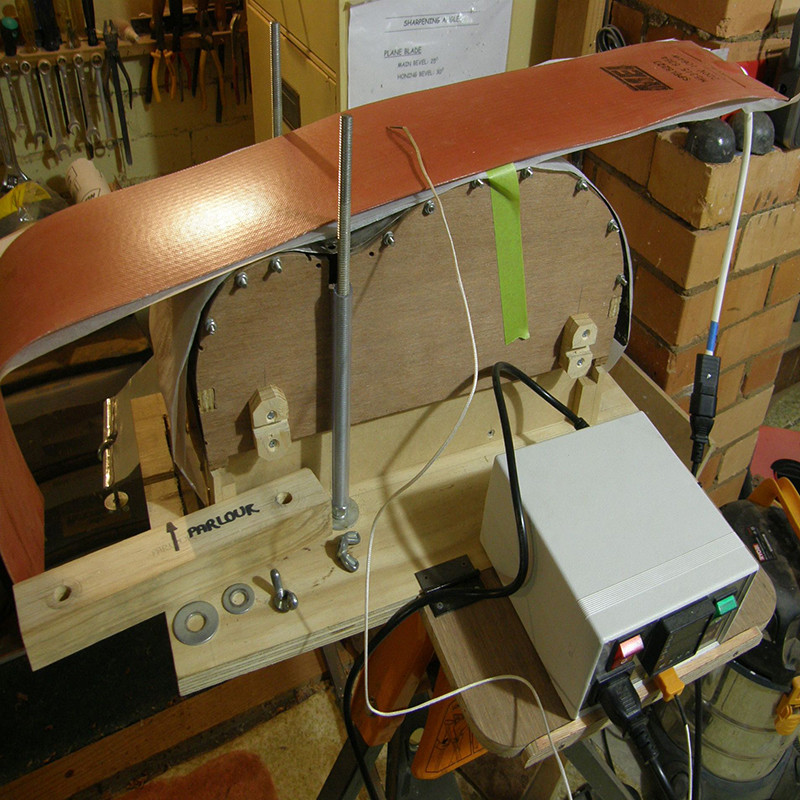

There is a thin metal sheet above and below the wood that make up a metal/wood/metal sandwich to stop the grain

breaking around the top surface, which is under tension. I use aluminum, though springy stainless steel is better in

some ways but very hard to work.

Here are the first two metal/bamboo layers of the sandwich, ready for the blanket and then the second metal sheet on

top. I put baking paper in between and give it a squirt of water to help the bend:

The heat is provided by a silicone rubber thermal blanket connected to a temperature controller. In the picture

below you can see the thermocouple temperature sensor and the controller that allows heater to work safely

and accurately.

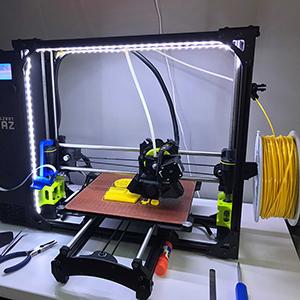

Here is what the bent side looked like after the first attempt at 180 degrees C, which is what the manufacturers

recommend. You can see that the waist doesn’t conform to the mould shape at all well, so I had to re-bend it

several times at higher temperatures before it came right, ending up at 230 degrees:

Here is one bent side clamped into the building half-mould while still warm to allow it to keep the bend: