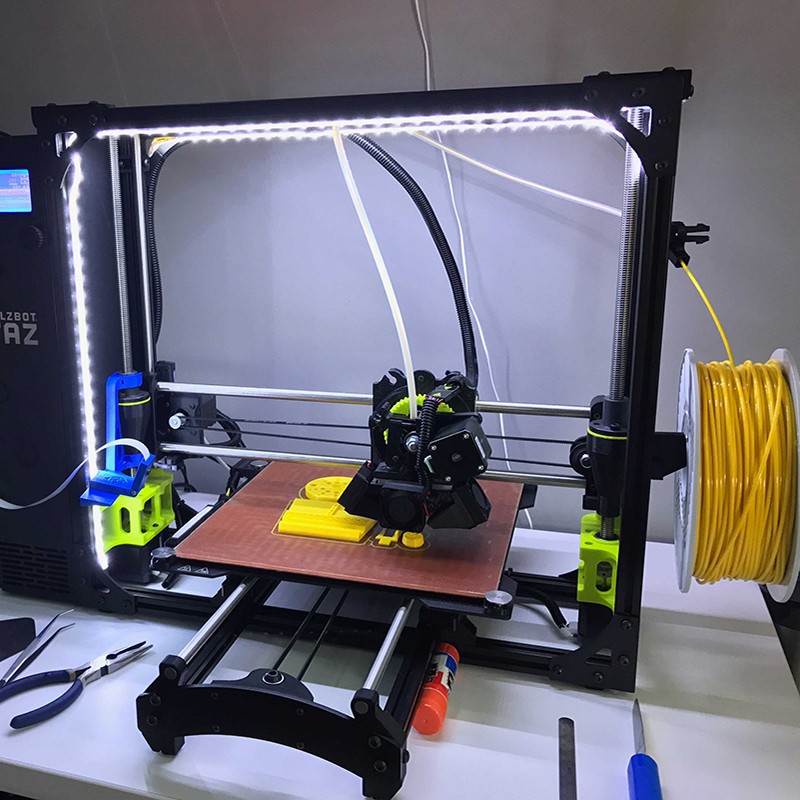

Why does 3D Printer need a silicone rubber heater?

Silicone heaters are favored for 3D printer heated beds due to their uniform heat distribution, fast heating, flexibility, durability, and energy efficiency.

They offer consistent temperatures crucial for quality prints, minimize downtime, and withstand high temperatures and prolonged use.

Here's a more detailed breakdown:

Silicone heaters provide even heat across the surface, preventing warping and improving first-layer adhesion.

They can quickly reach desired temperatures, reducing print preparation time.

Made from flexible and durable silicone rubber, they can conform to various shapes and withstand high temperatures.

Designed to be power-efficient, they help minimize energy consumption.

Silicone heaters can be customized in size and shape to fit specific printer needs.

Many silicone heaters come with built-in thermal fuses and insulation to prevent overheating and ensure safe operation.

Consistent heat helps prevent warping, improve layer adhesion, and ultimately leads to better print quality.

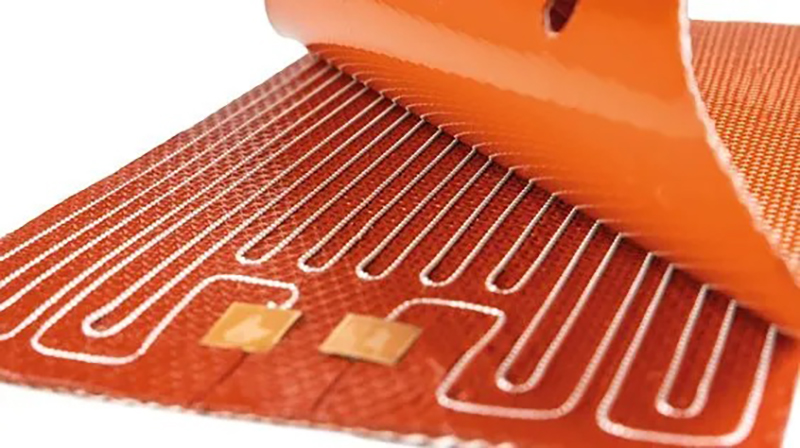

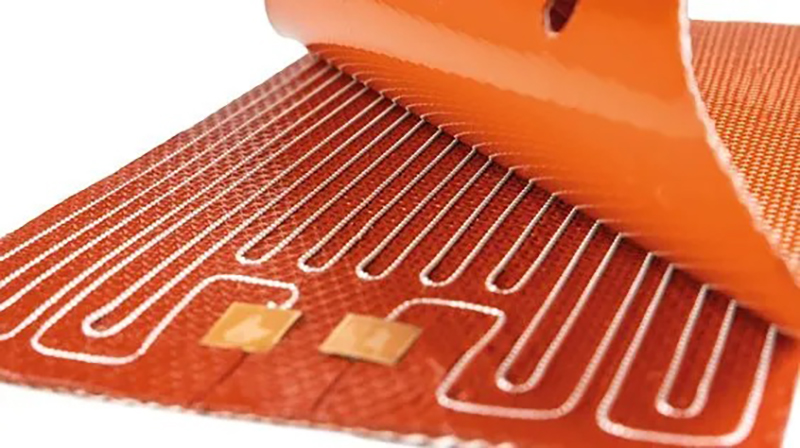

1) Wire-Wound Silicone Heater:

1-1) Silicone rubber heaters feature an advanced Wire-Wound Element, ensuring precise and uniform heat distribution.

1-2) Crafted with high-quality resistance wire, this element provides efficient warmth across the entire surface, making it ideal for applications requiring consistent heating.

1-3) Its exceptional flexibility allows the heater to conform seamlessly to complex shapes. Engineered for durability, the Wire-Wound Element withstands challenging conditions, offering a reliable and long-lasting heating solution.

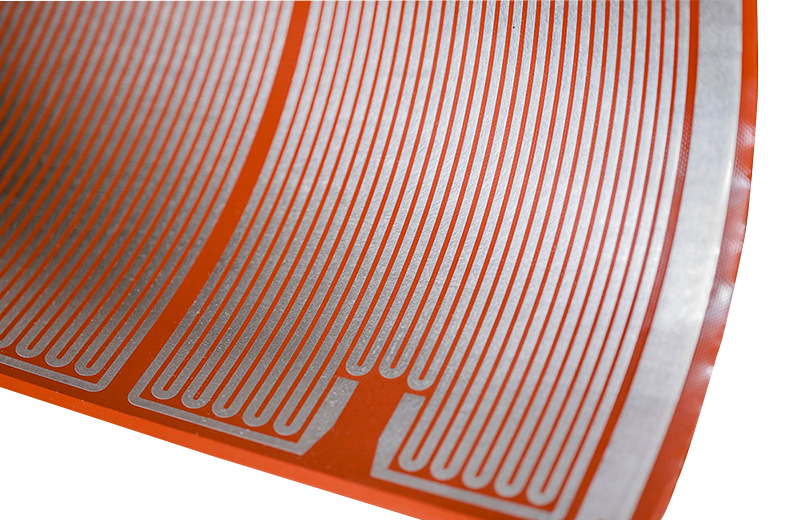

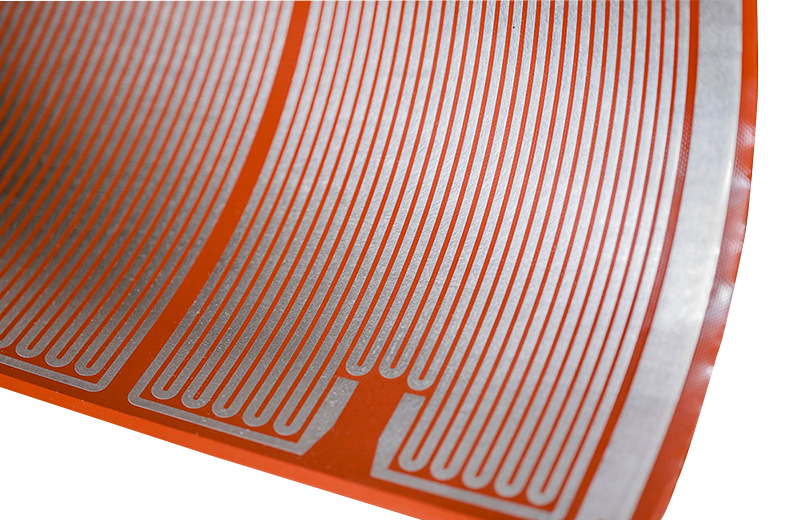

2) Etched Foil Silicone Heater

1-1) Silicone rubber heaters boast the innovative Etched Foil Element, setting new standards in precision heating. Characterized by its thin, flat design, this element ensures efficient and uniform heat transfer across the entire silicone rubber surface.

1-2) Its flexibility allows the heater to adapt seamlessly to complex shapes and contours, making it an ideal choice for diverse applications.

1-3) The meticulous construction of the etched foil enhances durability, providing resilience in challenging environments.

3) Specifications of Silicone Rubber Heaters

Material: | Silicone rubber/imported silicone+metal wire |

Size: | Customized(Min 10x10mm), no maximum length |

Thickness: | 1.5mm(±0.1mm) except at lead wire exit |

Voltage: | Customized |

Wattage: | 12 W/in² |

Lead wire: | 1000mm teflon wire |

Dielectric Strength: | 1250 VAC |

Maximum Temperature: | Heaters without pressure sensitive adhesive, 232°C (450°F); heaters with pressure sensitive adhesive, 180°C (356°F) |

Minimum Temperature: | -56°C (-70°F) |

Installation: | Double side adhesive, Spring, Screw holes, Vercro and so on..... |

Power connection method: | Plug, Connector and so on...

|